Unplugged: EV battery boom fizzles despite $28B in public help

Published in Business News

KOKOMO, Indiana — Two years ago, this city of 60,000 an hour’s drive north of Indianapolis was on the fast track to becoming an electric vehicle battery boomtown.

A Stellantis NV and Samsung SDI joint venture announced it would build a second battery gigafactory on the city's northeastern flank, next to the 2.4 million-square-foot facility that construction crews were already racing to erect.

Executives promised the $6.3 billion StarPlus Energy complex would eventually employ 2,800 people making batteries for the automaker’s planned lineup of EV Jeeps, Dodges and Rams — thrusting this blue-collar community long known for crafting gas-powered car parts into an electrified future. Taxpayers would back the project to the tune of up to $7.5 billion in federal loans, a record-setting $360 million or more in state-funded incentives and sweeping local tax breaks.

Those plans have run into grim realities.

Flagging demand, Chinese competition and sharp political shifts in Washington are forcing automakers from Detroit to Germany and beyond to make costly changes to EV plans in places like Kokomo. There, the second plant never broke ground. The first plant is up and running, but by last spring, it had laid off hundreds of hourly workers. More salaried job cuts followed over the summer.

Most hourly employees were recently called back, but not to build EV batteries. Starting last month, part of the plant pivoted to make batteries for energy storage, units often used to help stabilize electrical grids and support data centers. Another section of the facility is switching to make EV batteries for export to Europe, where demand is stronger; the automaker said development and testing for that program continue.

"The market right now does not support an EV manufacturing facility," said Frank Bush, 52, a utility mechanic at the plant who watched hundreds of his colleagues get laid off earlier this year when production stopped.

Across the Midwest and South — from Kokomo and Metro Detroit to Bowling Green, Kentucky, and beyond — the promises of a high-tech EV manufacturing revolution and the economic boost that comes with it are starting to fade.

Taxpayers committed at least $28 billion in combined loans, grants and similar subsidies to these massive projects across this Battery Belt region in recent years, a review by The Detroit News found — a sum that doesn't include several sites in western states, many local government tax breaks or federal tax credits. With EV demand sagging and government-backed incentives ending, many of these projects now face an uncertain future.

The goal under former President Joe Biden was to slash greenhouse gases and turbocharge a new domestic EV supply chain that could help the United States take on China. But EV customer demand wasn’t matching lofty government and industry sales projections even before President Donald Trump took office, thanks to a mix of range anxiety, sparse charging networks, high sticker prices and anti-EV political messaging.

Now, the Biden era's generous taxpayer subsidies and strict emissions standards designed to spur EV adoption are being quickly dismantled by Trump and a GOP-controlled Congress. The result: So far this year, nearly $23 billion in EV and battery manufacturing projects that involve more than 30,000 announced jobs have been canceled, according to data from Atlas Public Policy, a research group. Other projects like Kokomo are stalled, mothballed or face years-long delays.

The latest blow was September’s expiration of the federal $7,500 EV tax credit under the One Big Beautiful Bill budget act enacted over the summer. Ford Motor Co. CEO Jim Farley said demand for plug-ins could fall by half without the federal subsidy. A few weeks ago, General Motors Co. said it was laying off more than 3,400 workers across its battery plants and other EV facilities, including 1,200 at the Detroit-area EV plant Factory Zero. Chief Financial Officer Paul Jacobson recently said the company expects "EV demand growth to slow pretty significantly."

U.S. automakers still have their eyes on an electric future — but it’s not coming nearly as fast as expected.

That’s especially true for Stellantis. In 2022, the transatlantic automaker pledged 50% of its U.S. sales would be EVs by 2030. But it’s sold relatively few fully electric vehicles in the United States thus far, and now the company is pivoting back toward V-8 gas-guzzlers and hybrids as it embraces Trump's loosened emissions requirements.

At the moment, building another multibillion-dollar battery plant in the United States doesn’t appear necessary.

“The plans are in a drawer, on a shelf, in a hard drive somewhere,” said Conrad Layson, senior alternative propulsion analyst for AutoForecast Solutions LLC. “But the need, for the moment, has evaporated. And they need to see a consistent rise in demand.”

Vacant factories

Drive three hours south from Kokomo to the tiny farming community of Glendale, Kentucky, and a similar story is playing out at a planned $5.8 billion battery complex owned by Ford and the South Korean firm SK On.

Earlier this summer, one of the nearly mile-long factories the size of 60 football fields started producing its first batteries for Ford’s F-150 Lightning pickup, with plans to supply the E-Transit van later this year. But the second mega plant remains an empty shell, and local officials said they don’t believe the combined complex will reach its 5,000-worker goal anytime soon; about 1,450 people currently work there. Ford sold just 1,500 Lightnings and 260 E-Transits in October, its two worst-selling models.

BlueOval SK will watch demand and "be in position to respond as needed," spokesperson Keli McAlister said in an email. In the meantime, it's looking for customers outside Ford to pick up the slack. Amid the EV market slowdown, the joint venture has also postponed the start of battery production at its BlueOval City plant in Stanton, Tennessee, by two years until 2027.

Another hour’s journey south to Bowling Green, Kentucky, a partially finished battery plant from the Chinese-owned firm Automotive Energy Supply Corp., or AESC, looms over farm fields on the city’s outskirts.

The $2 billion factory had secured a commitment of up to $122 million in state taxpayer support and was supposed to open early this year to supply Mercedes-Benz Group AG, but neighbors said the construction site has been quiet for months. Several entrances were boarded up on a recent morning, and weeds sprouted from the surrounding construction site. AESC spokesperson Brad Grantham said the company continues to make infrastructure upgrades on the property involving the plant’s energy supply.

At its plant in Smyrna, Tennessee, AESC recently pivoted to making energy storage batteries after previously supplying EV batteries for the Nissan Leaf. Grantham said the company is now looking at replicating that shift to energy storage in Bowling Green.

Earlier this year, AESC also halted construction of a $1.6 billion EV battery plant in Florence, South Carolina, and Grantham said work on that project remains paused.

Local officials in Bowling Green — a college town of about 80,000 where the Chevrolet Corvette is built — either didn’t respond to, or declined, interview requests about the stalled battery plant. A city spokesperson, Deborah West, wouldn’t comment specifically on the project’s status but said in an email that the city remains focused on economic and workforce development efforts more broadly.

Michigan plants stumble

Michigan, too, is feeling the effects of a bleak EV battery market.

A planned $1.6 billion Our Next Energy factory in Van Buren Township, in line for $237 million in state taxpayer subsidies, was supposed to be bustling with workers by now. But much of the building remains a vacant shell with dirt floors, and some of the space is listed for lease. The Michigan Economic Development Corp. has so far disbursed $70 million in subsidies, spokeswoman Danielle Emerson said, but payments are now paused as MEDC seeks to understand "any updated scope of the project."

Mujeeb Ijaz, Our Next Energy's founder and CEO, said in an email that about 50 employees are working in one part of the building on battery cell production and development for defense purposes, and plans remain to eventually make energy storage batteries in another section. But the largest part of the building, intended to make EV batteries, "is being delayed due to automotive uncertainty."

Other Michigan examples abound: Mining firm Fortescue recently scrapped a $210 million, 600-job EV battery project underway in Detroit that was also in line for taxpayer funds but never received payments. BorgWarner shuttered two of its battery facilities in Hazel Park and Warren earlier this year, laying off 188 people. Freudenberg e-Power Systems is gradually closing its Midland and Auburn Hills facilities and cutting 324 jobs due to what it called a "decrease in demand for heavy-duty electric vehicles in North America."

Farther north, a legal battle snarled plans for a $2.4 billion Gotion Inc. battery plant in Mecosta County, and the project now appears dead. In mid-September, the state told Gotion it was in default of a $175 million taxpayer incentive agreement it promised the company.

GM pulled out of its Lansing-area EV battery project, meanwhile, selling its stake to joint-venture partner LG Energy Solution. LG gets to keep $120 million in previously approved state money and other incentives for the project, and now expects to start battery production sometime next year after plans were pushed back from 2024. It has at least one customer lined up in Toyota Motor Corp., the automaker confirmed.

At its battery plant in Holland, LG made costly changes so that it could make energy storage batteries and not EV ones, as was its original plan. Company spokesperson Sophia Kim wouldn't confirm if LG also expects to make some energy storage batteries at the Lansing facility, as a Korean publication recently reported.

Among the few projects forging ahead is Ford’s BlueOval Battery Park in south-central Michigan’s Marshall. The automaker slashed the size of the project, originally pegged to cost $3.5 billion, in late 2023 as EV demand appeared less certain, reducing gigawatt capacity by about 43% and cutting projected employment to 1,700 from around 2,500. A state incentive package was reduced to no more than $409 million from about $1 billion.

But Ford pledges it will finish the project and start production next year, after lawmakers said it would still qualify for Biden-era manufacturing tax credits despite the automaker’s licensing agreement with a Chinese battery firm, Contemporary Amperex Technology Ltd., or CATL.

Ford says it needs the Marshall plant to produce a cheaper, lithium-iron-phosphate type of battery that will be critical to making less-expensive EVs of the future — including a midsize truck it plans to build at its Louisville Assembly Plant. The BlueOval SK factories in Kentucky and Tennessee are set up to make a more common type of battery using nickel, manganese and cobalt.

Choose Marshall, the local economic development agency, recently said the project has hit milestones, including hiring an initial round of more than 100 plant employees, employing 2,200 construction workers, and making initial property tax payments that will eventually total about $5 million per year. The automaker says exterior construction is complete and work is now focused on outfitting the interior.

But the project also continues to draw scrutiny from a group called “Committee for Marshall — Not the Megasite,” including over how the property was rezoned as well as environmental and traffic concerns. The resident group recently secured a legal victory from the Michigan Supreme Court, which ordered a lower court to reconsider the committee’s challenge of the project; the group is now waiting on that updated decision.

"Our group isn't opposed to progress; we just want to make sure people have a say in what's developed, and that it's not all industrial development, and fits the character of the area,” said Regis Klingler, a Marshall resident who chairs the committee.

Klingler acknowledged it would be a long shot to stop Ford from finishing the plant now. But the group hopes to secure more public input and transparency around future projects proposed for an adjacent 1,500 acres.

“The war’s not over," he said. "The legal battle’s not over."

'Supposed to be halfway'

In Kokomo, Mayor Tyler Moore said there’s a “gray cloud” looming over the EV industry that’s affected plans at his city’s StarPlus Energy plant, including construction on the second factory.

"They were already supposed to be halfway through or working toward completion of the second battery plant by now,” he said. “So yes, there's concerns that they're slow-rolling that, and of course, there's a lot of chatter when you hear of layoffs, or lines being retooled and such."

But Moore, a Republican, is cautiously optimistic that the project will come to fruition eventually, just on a slower timeline.

The first plant has already made a profound impact on the city, he said, from suppliers setting up shop nearby to a large influx of Korean nationals from Samsung who have arrived in town to help get the plant running.

“One of the joys has been ... we went from no Korean restaurants to six,” said the mayor, whose business card now includes Korean translations. “It’s been fun to be a part of that, and see that come, and then see the community embrace it as well.”

And Moore said there’s evidence that the second project will eventually proceed. The joint venture obtained billions of dollars in loans from the U.S. Department of Energy last year. It bodes well that Samsung SDI has a diverse battery product line that it can turn to beyond EVs, he said, including energy storage. And Stellantis has a longstanding manufacturing presence and relationships in the city; the automaker recently committed to producing a new gas-powered engine in Kokomo, pumping $100 million into existing plants and adding 100 jobs in the next few years.

Stellantis spokesperson Jodi Tinson said plans to construct the second battery plant “will be developed considering the current market conditions,” and with an eye toward maintaining flexibility.

“I will be glad when we get more directions on where Stellantis is heading with EVs, what our projections are coming up," said Dave Willis Sr., president of United Auto Workers Local 1166, which represents more than 400 workers at the facility, many of whom were recently laid off for months. "There's a lot of major questions that are still in the air."

A silver lining of the battery plant delays is that they offer the city and developers extra time to build new housing for an influx of workers, Moore said. Kokomo was grappling with a shortage even before the StarPlus projects were announced.

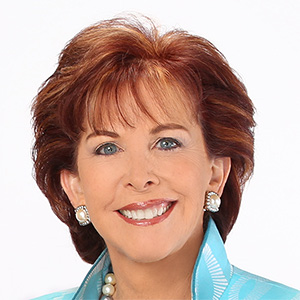

Not everyone was convinced by the city’s bet to become a major North American EV battery producer. Al Taylor, 71, a former Chrysler plant worker who now curates the city’s Elwood Haynes Museum, which honors an inventor who built one of the first automobiles, said the jobs promised by the StarPlus project were certainly attractive.

But he was always skeptical about whether there would be enough EV demand to keep the factory’s lights on. Taylor doesn’t see many EVs rolling around Kokomo; the bank of chargers at the local Meijer often sits empty. And EV prices also appear out of reach.

“They are expensive,” said Taylor, who drives an older pickup. “It just doesn’t seem, for a middle-class person like myself, a senior citizen on a fixed income, I (could afford) to buy one.”

Bush, the StarPlus worker, said given the slowing EV market, it was smart for his plant to pivot to making energy storage batteries, which will help keep it open. But he and other workers who spoke with The News said they're not confident it will bring enough work to add more staff or justify building the second plant.

Daniel Jackson was among the dozens of salaried StarPlus workers laid off over the summer, just a few months after hundreds of hourly workers were cut. The 37-year-old was thriving in his job as a production supervisor over a small team assembling batteries. The pay was solid at about $84,000 per year, he said, and the benefits generous; much of the work was highly automated, making the 12-hour shifts tolerable.

"I'm going to be there forever," Jackson said he figured when he was hired last year, noting at that point plans for the second plant were still moving forward. "I'm thinking to myself, 'This battery stuff is the new hot thing.'"

But the mood inside the plant shifted quickly, and by summer, production was stopped and he and other managers were mostly left to clean, organize and maintain machinery as they pondered how long it would be until more layoffs hit. After losing his job in August, Jackson eventually found work at a nearby steel mill, but he said it doesn't compare to his old gig at StarPlus.

Shift to energy storage?

More stalled EV battery factories are likely to explore building batteries for energy storage instead, experts said. The stationary units range in size from a large suitcase up to a shipping container or bigger, and can help stabilize the electrical grid or provide backup power in emergencies.

Companies, including AESC, LG Energy Solution and now StarPlus Energy in Kokomo, have already begun the conversion process at their plants. SK On, Ford's partner in Kentucky, recently said it would use part of its Georgia EV battery plant to start building some.

The pivot will require major overhauls to equipment and production lines. But the goal is to prevent these multibillion-dollar facilities — originally designed to churn out hundreds of thousands of EV batteries per year — from becoming unused “stranded assets,” said Layson, the AutoForecast analyst.

Such battery storage systems are in hot demand to help power data centers and hold on to energy produced by solar and wind projects. And analysts pointed out that battery storage technology still qualifies for key federal subsidies, even as EV tax credits have been slashed under the Trump administration.

A recent Samsung SDI investor presentation says that while domestic EV demand is uncertain thanks to looser emissions standards, repealed subsidies, and higher tariffs under Trump, battery storage is “growing as renewable energy generation and AI demand expands.”

“What I expect is we’ll see more and more of a shift in production from EV batteries to battery storage,” said Tom Taylor, a senior policy analyst with Atlas Public Policy.

Taylor noted that there are a handful of major EV projects still pressing forward, despite the headwinds — such as a new Rivian Automotive Inc. plant in Georgia, Slate Auto’s first factory in Indiana, and a transformed Ford EV production line in Kentucky. But the overall EV and battery industry, he said, “has been hit hardest of all the technologies we track.”

UAW President Shawn Fain recently told union members he believes the pullback in automaker EV investments and layoffs is wrong-headed, even if the companies are facing fewer federal incentives and a more sluggish market than expected.

"It's a choice by the companies to not invest in what we know is going to be the future," he said. "The electric vehicle market is still growing — you look at China, they're now the largest exporter of vehicles in the world, and many of them are electric."

'Too many battery plants'

The BlueOval SK project in Glendale was hailed as the largest economic development project in Kentucky’s history.

It secured $250 million worth of direct state taxpayer-funded support, tens of millions for workforce development and a local training center, local tax breaks that extend for years, and a $9.6 billion federal loan that also goes toward the company's project in Tennessee.

One report estimated the battery plant would create a boomtown effect requiring nearly 9,000 more housing units in surrounding Hardin County, adding thousands more schoolkids and requiring more hospital beds. Gov. Andy Beshear, a Democrat, called the project “our game changer.”

The reality on the ground hasn’t lived up to that original hype, given the current depressed state of the EV industry and the complex’s only partial buildout.

But Andy Games, who heads the Elizabethtown-Hardin County Industrial Foundation, views the delays as unsurprising speed bumps for what is essentially a start-up company. He’s confident EVs remain the future, but in the meantime, he believes the plant can pivot and make something else.

"To me, they've got 4 million square feet under-roof ready to do whatever — they're in the business of making money,” Games said of the second empty facility. “Why couldn’t you do storage batteries, or any type of battery?”

The project has already had sweeping effects on the county and Elizabethtown, he said — several thousand new apartment units, new subdivisions, a couple of new grocery stores, even an investor who wants to refresh the old local mall. Around a billion dollars of additional investments were pledged locally by other companies after the original BlueOval SK announcement.

Like Kokomo, large numbers of Korean engineers and others have also arrived to work at the plant and train new employees. Yet the factory and its promised windfall of jobs has also brought headaches in the form of strained budgets, said Keith Taul, the county’s judge-executive who was elected to the post after the project had been largely finalized.

He said tax breaks used to attract the project mean the county is trying to figure out how to do more without any new local tax revenue, including property taxes.

"The problem, of course, is that the county doesn't get any revenue. And so we've got this massive project, and the pressure that brings with more population, more stuff going on in the county,” said Taul, a Republican farmer and former auto supplier executive, listing off costs tied to emergency services, the sheriff’s department, road and bridge maintenance, a county jail, more full-time firefighters needed near the plant, and more.

"All of these things are impacted by a project. So the question is, how do you pay? How do you pay for the additional population and wear and tear on the infrastructure?"

Like Moore in Kokomo, Taul sees the plant’s slower-than-expected growth as something of a blessing in disguise. It gives him and other local leaders more time to figure out how to add services and infrastructure over the next few years.

Closer to the factory, in unincorporated Glendale, long known for antique stores and a big fall festival, opinions vary on the new mega plant that now defines the town’s image. Mary Spak, who owns a shop called Small Biz Market, said many residents say the plant is ruining Glendale’s small-town charm. The 31-year-old, though, sees it as potentially breathing new life into the area.

More traffic turns through the quaint downtown now, and the local coffee shop gets steady business. She knows the plant seems to be struggling at the moment, but figures it will “have to produce something. It’s not going to end up sitting empty.”’

Sheree Vance, who some call Glendale’s unofficial mayor, was frustrated by construction road closures that killed customer traffic to her business over the last couple of years. She worries about developers snapping up farmland around the factory and altering Glendale's rural way of life.

And she's not confident it will ever reach its employment goals, anyway. “I don’t know that it can ever be at capacity,” the 68-year-old said, sitting on a bench outside her antique store called The Side Track Shops.

“They’ve ended up building too many battery plants, too many places,” Vance said. “Just bottom line, when the government throws money at you, you spend it, and that doesn’t always work out the best.”

©2025 www.detroitnews.com. Visit at detroitnews.com. Distributed by Tribune Content Agency, LLC.

Comments