Boeing expects more changes at supplier Spirit Aero as merger approaches

Published in Business News

As Boeing prepares to fold supplier Spirit AeroSystems back into the company, executives shared additional details on last year's rush to improve quality control at the troubled Kansas factory.

In just five weeks, Boeing and Spirit set up a new inspection checkpoint at the end of Spirit's Wichita, Kansas, production line. There, teams of inspectors would review seven fuselages at once, working to reduce the number of flawed 737 fuselages arriving at Boeing's Renton, Washington, plant for final assembly.

The project — in response to an Alaska Airlines panel blowout in January 2024 that revealed shortcomings in Boeing and Spirit’s production process — was part of a new inspection regime, which included more inspectors, more inspections and a new set of metrics to track fuselage quality.

It was a larger undertaking than even Boeing realized at the time, said Doug Ackerman, the vice president of quality for Boeing Commercial Airplanes.

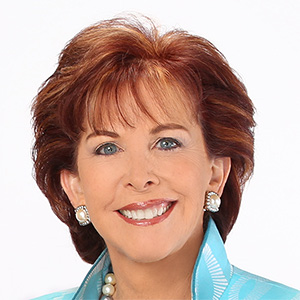

“The scale of what we were committing to do was not apparent when we first did it,” Ackerman said in one his first media interviews since stepping into the VP of quality role in December 2024.

In addition to its new inspection regime, Boeing decided in July 2024 it would reacquire Spirit, hoping to improve quality by bringing the company back under one umbrella after spinning it out roughly 20 years ago. That acquisition is still pending but executives have said they expect it will be finalized this year.

Scott Grabon, Spirit’s senior director for 737 quality, told regulators at a grueling two-day public hearing in front of the National Transportation Safety Board last year that the final checkpoint was “probably the biggest change” made after the panel blowout to improve the quality of fuselages leaving Spirit’s factory.

But Ackerman hopes to get to a point where that final check isn’t needed. He wants to move the inspections into the production process, beefing up existing inspections and evaluating production work as it is happening, rather than at the end of the line.

“In any production system, you really want to have an inspection done as close to where the original work is done as possible,” Ackerman said. “You want the direct feedback. You want the shortest flow between the time a defect is created and the time it's identified.”

That’s why Boeing set up the final check at Spirit, inspecting the fuselage and completing any repairs before it travels to Renton, where defects would be more difficult and costly to repair.

In the case of the Alaska Airlines incident, investigators now know that Boeing mechanics in Renton, repairing mistakes made in Wichita, failed to properly secure the piece, leading it to blow off midair and open a gaping hole in the side of the plane.

“Eventually we would like to not have” a final check, Ackerman said. “But we’ll do that when the data says that we’ve effectively moved all the inspections back further” in the production process, checking for mistakes in almost real-time.

How does final product verification work?

Ackerman, who was Boeing’s vice president of supplier quality and fabrication at the time of the panel blowout, said he remembers clearly the decision to set up the final checkpoint, known as final product verification.

The blowout occurred on Jan. 5. Boeing told Spirit on Jan. 25 it would need to inspect every fuselage before it left the Wichita factory. It set a March 1 deadline.

The companies cleared space in an adjacent building on Spirit’s Wichita campus and set up positions for seven fuselages to be inspected. It later increased that number to nine.

“It was a lot to industrialize,” Ackerman said. “Getting it to operate at the pace of a production system was not an insignificant challenge. … It’s going well (now) and has been for a while, but I can’t think of a corollary in the industry where something of that magnitude was put in place that fast.”

After a fuselage is inspected on the final product verification line — and any repairs are completed — it is loaded onto a rail car and shipped to Renton. There, Boeing inspects the fuselage again, for any defects that may have slipped through and any impact from the train ride over.

Boeing calls that job, which was in place long before the panel blowout prompted changes last year, “OK to Install.” Every fuselage must pass review before mechanics start adding new parts to the plane.

That’s one example of the redundancy that’s built into Boeing’s inspection process, said Brett Lewis, the director of engineering for 737, who joined Ackerman in the recent interview.

“Not only do we have inspectors in certain areas, like skin inspectors that will do the skin, but mechanics are also looking for defects as well,” Lewis said. “Everyone is looking. If there are any quality issues, then they’ll raise their hand and that defect will be documented. There’re multiple ways of inspections.”

Boeing and Spirit have a “daily feedback loop,” Ackerman said, to discuss the quality of each individual fuselage, as well as any trends.

What comes next?

The idea that Boeing wants to keep inspections close to the original work isn’t new or unique to Ackerman.

Boeing CEO Kelly Ortberg told analysts last October that the company was “making good progress in pushing the defects back into the system to where they’re originating and then getting that root cause to fix those.”

Boeing was already seeing improvement in the quality of fuselages arriving from Spirit then, Ortberg said, and expected there would be “even a step change improvement from where we are today.”

In the interview this October, Ackerman agreed that Spirit has been “aggressive” in tackling production issues, and has invested in new technologies to lower the risk of error.

The next big change at Spirit should come this year, when Boeing finalizes its acquisition of the supplier. Boeing and its European competitor Airbus said in July 2024 the two companies would carve up Spirit, taking ownership of the parts of the company that produce aircraft parts for each manufacturer.

Earlier this month, the European Union cleared Boeing’s acquisition, marking another step toward final regulatory approval.

Ackerman said the pending acquisition wouldn’t impact Boeing’s decision about when and where to inspect the fuselages, or how long it will keep the final checkpoint up and running.

“The regime of inspections won’t change because of an ownership change,” he said. “It’s about inspecting the product, not who owns it.”

©2025 The Seattle Times. Visit seattletimes.com. Distributed by Tribune Content Agency, LLC.

Comments